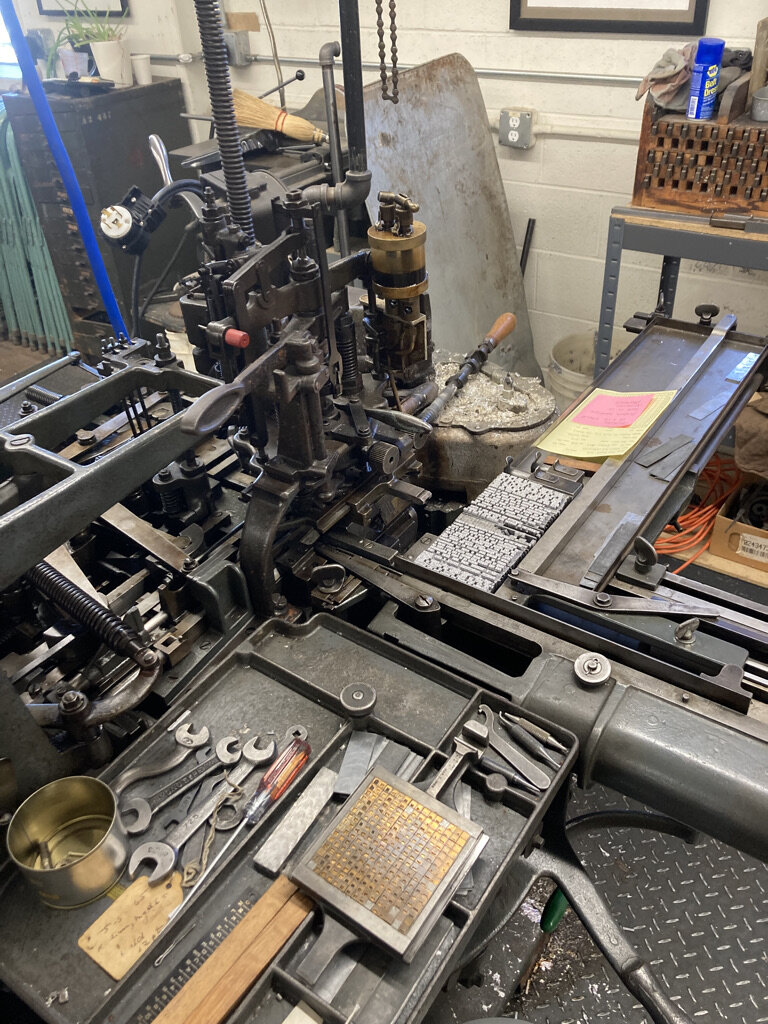

Today I discovered that lizards live in this part of the world. In the cold rainy Pacific Northwest. Approximately 45 minutes from where the film "Goonies" was shot. If that helps you get a picture of how very un-lizard this environment is, or at least one would think so. But, sure enough. Lizards. Not Salamanders. How did I learn this? Our resident lizard told me. I'm at the new location of the print shop, also the new location of the C.C. Stern Type Foundry. Or rather, soon to be. Construction is under way. It's a place we're calling "Type Hive" in part because two owners of the property are beekeepers, and in part because it is a "hive" of print activity. But now, it's quiet. And this lizard tells me that we disrupted its house during our construction. Which was a strange thing, because the lizard and I don't speak the same language, but I knew. We are making a path from the new Type Foundry building to the Print building. That's where the lizard was living. Under some bricks which were recently moved. Of course we didn't know that before we moved the bricks. After the lizard confronted me, I realized that its home was quite nice. Those bricks held whatever southern sun warmth was available in this otherwise cold and wet environment. The lizard is a Northern Alligator Lizard. Life span up to 10 years. Imagine that. The brick move happened about 5 days ago. The lizard had "words" with me today. It didn't leave the area where its original house was. I'm hoping that this means the lizard will find its new digs acceptable. I re-built a brick house for it, near the original home but out of the way of the direct path of the new Type Foundry building. I made sure that the new structure is south facing, and added multiple entrances and pathways to the new home. It's a decent place. Or seems to be. I hope the lizard moves in.

Resident Northern Alligator Lizard near the new C.C. Stern Type Foundry Building